Mill Rolls are important tools and key components for rolling ferrous metal materials. The cost of mill rolls is about 5%~15% of the rolling steel production, which is directly related to the production efficiency, product quality and production cost of the steel enterprises.

Mill Rolls can be divided into casting rolls and forging rolls, both of them have high hardness and large allowance, and are difficult to process. Especially for the large casting rolls with the casting defects such as sand, stomata and hard spot , it will required very high on the cutting tools.

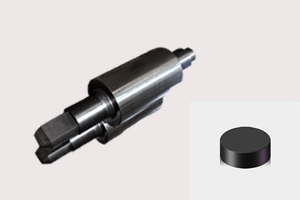

Specific for the high hardness rolls, Halnn Superhard recommend Solid CBN inserts which can be used for large margin cutting. Compared with the traditional cutting tools, the performance will be more stable, the production efficiency will be improved, and the dry cutting applications significantly reduced the production costs.

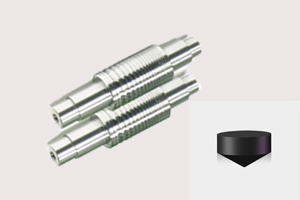

Halnn cbn inserts include BN-K1 and BN-S20 which belongs to non-metallic binder solid cbn inserts aiming to above problems.

(1) BN-K1 solid cbn insert is suitable for high hardness cast iron industry

(2) BN-S20 solid cbn insert is suitable for high hardness steel/ forging steel industry.

Both two grades solid cbn inserts are used for roughing and finishing process. The cutting parameters were shown as below:

|

Roll Materials |

Woekpiece hardness | Halnn Grade | Cutting Parameters | Insert Image | ||

| Alloy Cast iron | HSD60~80 | BN-K1 | Vc=40~60m/min,ap=2~10mm,Fr=0.5~1.5mm/r, Vc=60~90m/min,ap=1mm,Fr=0.5~1mm/r |

|

||

| Cast Semi-Steel | Vc=30~60m/min,ap=1~10mm,Fr=0.5~1.5mm/r, Vc=50~80m/min,ap=1mm,Fr=0.5~1mm/r | |||||

| High Carbon Semi-Steel | Vc=35~50m/min,ap=1~10mm,Fr=0.5~1mm/r | |||||

| Chilled Cast iron | Vc=25~50m/min,ap=1~10mm,Fr=0.5~1mm/r | |||||

| High Speed Cast Steel | HSD85~92 | BN-S20 | Vc=20~45m/min,ap=4 mm,Fr=0.5~1.5mm/r | |||

| Forged Steel | HRC65 | BN-S20 | Vc=90m/min,ap=4 mm,Fr=0.2~0.7mm/r | |||

1. Halnn Superhard solid cbn inserts BN-K1 processing Cylindrical of the cast iron rolls:

|

BN-K1 Solid CBN inserts processing Cylindrical of the cast iron rolls

|

|||||

|

Machining Materials: |

High Nickel-Chromium Alloy Cast iron

|

|

|||

|

Workpiece Hardness:

|

HSD80

|

||||

|

Insert Model:

|

BN-K1 RNMN200800

|

||||

|

Machining Type:

|

Dry Cutting

|

||||

|

Cutting Parameters:

|

Vc=55m/min,ap=4mm,Fr=1mm/r

|

||||

|

Machining Effect

|

|||||

|

Insert Materials

|

Feed Rate

|

Insert Life/blade

|

Failure Mode

|

||

|

Halnn BN-K1 CBN

|

1 mm/r

|

3 pcs

|

Normal Wear

|

||

|

Ceramic Insert

|

0.5 mm/r

|

0.5 pcs

|

Chipping

|

||

2. Halnn Superhard solid cbn inserts BN-S20 process the grooves of high speed steel rolls:

|

BN-S20 Solid CBN inserts process the grooves of high speed steel rolls

|

||||

|

Machining Materials: |

High-Speed Steel

|

|

||

|

Workpiece Hardness:

|

HSD90

|

|||

|

Insert Model:

|

BN-S20 RCMX120700

|

|||

|

Machining Type:

|

Dry Cutting

|

|||

|

Cutting Parameters:

|

Vc=50m/min,ap=1mm,Fr=0.2mm/r

|

|||

|

Machining Effect

|

||||

|

Insert Materials

|

Process Tact

|

Insert Life/blade

|

Efficiency Improved

|

|

|

Halnn BN-S20 CBN

|

2h

|

25 grooves

|

6 times

|

|

|

Carbide Insert

|

12h

|

3 grooves

|

……

|

|

From above application case, we can see that Halnn CBN insert perform better than other Ceramic Insert and Carbide Insert, and it will have similar effect with international brand insert, but with more reasonable price.