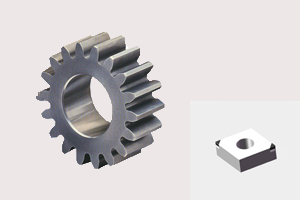

There are many difficulties on hard turning Gear after heat treating:

(1)The hardness of the Gear will reach HRC58~62, the insert will wear rapidly, which will affect the processing efficiency.

(2) Some Gears exist interrupted turning condition (end surface has hole), the cutting tools will be easily chipping, so the costs will be high.

(3) For large scale Gears, the hardness after heat treating will be high, and the deformation also will be large, it will require high wear resistance and impact resistance on the cutting tools.

Specific to above difficult problems, Halnn Superhard researched solid cbn inserts grade BN-S20 for roughing with large working allowance and pcbn inserts BN-H11, BN-H21, BN-H20,BN-H10 for finishing, which will make sure the excellent wear resistance, strong impact resistance and anti-fracture properties. The Inserts Grade and corresponding cutting data as follows:

|

Insert Grade

|

Machining Hardness

|

Machining Type

|

Machining Materials

|

Machining Area

|

Cutting Speed Vc(m/min)

|

Depth of Cut ap(mm)

|

Feed Rate f(mm/r)

|

|

BN-S20

|

HRC45~68

|

Roughing

|

|

|

50~200

|

1~10

|

0.15~0.1

|

|

Finishing

|

60~250

|

≤1

|

0.05~0.35

|

||||

|

BN-H10

|

HRC45~63

|

Finishing

|

|

|

60~250

|

≤1

|

0.05~0.35

|

|

BN-H21

|

HRC60~68

|

Finishing

|

|

|

60~250

|

≤0.5

|

0.05~0.35

|

|

BN-H11

|

HRC45~68

|

Finishing

|

|

|

90~200

|

≤1

|

0.05~0.35

|

|

BN-H20

|

HRC45~63

|

Finishing

|

|

|

60~180

|

≤1

|

0.05~0.35

|

1. Continuous Turning Condition: Halnn CBN inserts processing the inner bore of the Gears

|

BN-H10 PCBN Insert finish turning Gear Inner Bore

|

||||||

|

Machining Workpiece:

|

Gears

|

|

||||

|

Machining Type:

|

Continuous Finish Turning

|

|||||

|

Machining Part:

|

Inner Bore

|

|||||

|

Workpiece Hardness:

|

HRC58~62

|

|||||

|

Insert Model:

|

BN-H10 CNGA120408

|

|||||

|

Processing Type:

|

Dry Cutting

|

|||||

|

Cutting Parameters:

|

Vc=180m/min,Fr=0.1mm/r,ap=0.2mm

|

|||||

|

Machining Effect

|

||||||

|

Insert Materials

|

Cutting Speed

|

Insert Lifetime

|

Productivity

|

|||

|

Halnn BN-H1

|

180 m/min

|

800 pieces/blade

|

6 S

|

|||

|

Ceramic Insert

|

130 m/min

|

150 pieces/blade

|

8.5 S

|

|||

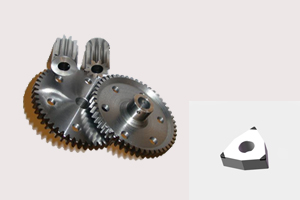

2. Semi-interrupted turning condition: Halnn CBN inserts machining the inner bore of the Gear Wheel

|

BN-H21 PCBN Insert processing Gears Inner Bore

|

|||||

|

Machining Workpiece:

|

Gears

|

|

|||

|

Machining Type:

|

Semi-interrupted Turning

|

||||

|

Machining Part:

|

Inner Bore

|

||||

|

Workpiece Hardness:

|

HRC58~62

|

||||

|

Insert Model:

|

BN-H21 WNGA120408

|

||||

|

Processing Type:

|

Dry Cutting

|

||||

|

Cutting Parameters:

|

Vc=120m/min,Fr=0.1mm/r,ap=0.25mm

|

||||

|

Machining Effect

|

|||||

|

Insert Materials

|

Cutting Speed Vc(m/min)

|

Insert Lifetime

|

Tool Cost/pcs

|

||

|

Halnn BN-H21

|

120

|

700 pieces/blade

|

USD 0.015

|

||

|

Other PCBN insert

|

120

|

650 pieces/blade

|

USD 0.03

|

||

3. Heavy Interrupted turning condition: Halnn CBN inserts processing the end surface of the Gear

|

BN-H21 PCBN Insert for Heavy Interrupted Turning

|

|||||

|

Machining Workpiece:

|

Gears

|

|

|||

|

Machining Type:

|

Heavy Interrupted Turning

|

||||

|

Machining Part:

|

End Surface

|

||||

|

Workpiece Hardness:

|

HRC58~62

|

||||

|

Insert Model:

|

BN-H21 WNGA120408

|

||||

|

Processing Type:

|

Dry Cutting

|

||||

|

Cutting Parameters:

|

Vc=300m/min,Fr=0.1mm/r,ap=0.3mm

|

||||

|

Machining Effect

|

|||||

|

Insert Materials

|

Cutting Speed Vc(m/min)

|

Depth of Cut ap(mm)

|

Insert Lifetime/blade

|

||

|

Halnn BN-H21

|

300

|

0.3

|

600 pcs

|

||

|

Other PCBN insert

|

300

|

0.3

|

450 pcs

|

||

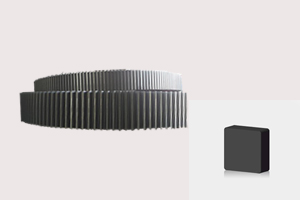

4. Heavy interrupted turning condition: Halnn CBN inserts processing the large scale Gear

|

BN-S20 Solid CBN Insert for Heavy Interrupted Turning Large Scale Gear

|

||||||

|

Machining Workpiece:

|

Large Scale Gear Wheel

|

|

||||

|

Machining Part:

|

Cylinder

|

|||||

|

Machining Materials:

|

Hardened Steel

|

|||||

|

Processing Type:

|

Fine Finishing

|

|||||

|

Workpiece Hardness:

|

HRC60

|

|||||

|

Machining Type:

|

Heavy interrupted cutting

|

|||||

|

Insert Model:

|

BN-S20 SNGN120712

|

|||||

|

Cutting Parameters:

|

Vc=90m/min,Fr=0.12mm/r,ap=2.5mm

|

|||||

|

Machining Effect

|

||||||

|

Insert Materials

|

Cutting Speed(m/min)

|

Tool Life/edge

|

Failure Mode

|

|||

|

Halnn BN-S20

|

90

|

5 pcs

|

6 s/pcs

|

|||

|

Some European PCBN insert

|

45

|

0.3 pcs

|

8.5 s/pcs

|

|||

In Processing Gear Industry, Halnn has so many CBN inserts grades, such as BN-S20 hard turning tools for heavy interrupted turning condition which can bear the impact of tooth surface. With Halnn solid cbn inserts, it can achieve excellent performance with reasonable price. And it can replace international famous brands, such as Seco and Sumitomo PCBN insert.