As we all know, the Mining Industry will need many wear resistant parts. If the wear resistant parts are not well, it will affect the working the efficiency increasing processing costs. They will need the parts with excellent wear resistance. So the manufacturers need to search the good cutting tools specific for these demands from their customers.

Halnn, as the leader of cutting tools industry in China, has researched many cbn inserts grade specific for the wear resistant parts. The grades and corresponding parts as below:

|

Insert Model

|

Processing Condition

|

Suited Materials

|

Machining Type

|

Feed Rate

|

Cutting Speed

|

Depth of Cut(mm)

|

|

BN-K1

|

Roughing

|

|

|

0.15~0.7

|

35~120

|

1~10mm

|

|

Finishing

|

|

0.05~0.35

|

60~180

|

≤1mm

|

||

|

BN-S20

|

Roughing

|

|

|

0.15~0.1

|

50~200

|

1~10

|

|

Finishing

|

|

0.05~0.35

|

60~250

|

≤1

|

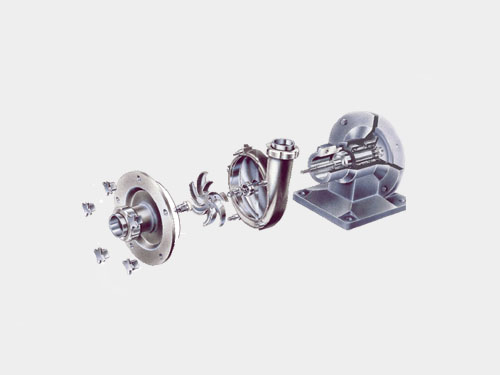

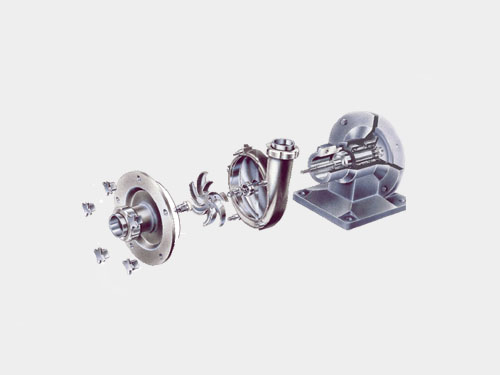

1. BN-K1 solid cbn inserts processing wear resistant casting parts industry pumps

BN-K1 process pump industry parts pump body cases (shown as below).

High chromium cast iron is the third generation white cast iron which is developed after common white cast iron, Ni-hard cast iron. Current high chromium cast iron is already recognized superior wear-resistant materials, mining, cement, electricity, road construction machinery and other aspects application is very extensive.

|

BN-K1 Solid CBN Insert processing Industry Pump Impeller

|

|||||

|

Machining Process:

|

Finish Machining

|

|

|||

|

Machining Part:

|

Industry Pump Impeller

|

||||

|

Machining Materials:

|

High Chromium Cast iron

|

||||

|

Insert Model:

|

BN-K1 CNMN120712

|

||||

|

Materials Hardness:

|

HRC60 | ||||

|

Processing Type:

|

Interrupted Turning,Dry Cutting

|

||||

|

Cutting Parameters:

|

ap=5mm,Fr=0.1mm/r,Vc=75m/min

|

||||

|

Machining Effect

|

|||||

|

Cutting tools material

|

Cutting speed

|

Linear Speed

|

Failure Mode

|

||

|

Halnn BN-K1

|

75m/min

|

7 pcs

|

Normal Wear

|

||

|

Ceramic inserts

|

35m/min

|

1 pcs

|

Chipping

|

||

Processing effect:Compared to ceramic inserts :When cutting speed of Halnn Superhard solid cbn inserts BN-K1 is 2 times of ceramic insert, feed rate is 42% more than ceramic insert, the life of single blade of BN-K1 will be 7.5 times than ceramic insert.

2. BN-S20 processing High Manganese Parts Rolling Mortar Parts

BN-S20 Solid CBN insert can be used for both roughing and finishing on processing concave.

(1)When rough machining, cutting parameters as follows: Vc=85m/min,Fr=0.25~0.8mm/r,ap=2~3.5mm

(2)When Fine Finishing, cutting parameters as follows:ap=0.5~1mm;Fr=0.15mm/r;v=135m/min

The Application Case will be as follows:

|

BN-K1 Solid CBN Insert processing Pump Body

|

||||

|

Machining Process:

|

Finish Machining

|

|

||

|

Machining Part:

|

Industry Pump Body

|

|||

|

Machining Materials:

|

High Chromium Cast iron

|

|||

|

Insert Model:

|

BN-K1 SNMN120712

|

|||

|

Materials Hardness:

|

HRC60

|

|||

|

Machining Condition:

|

Dry Cutting

|

|||

|

Cutting Parameters:

|

ap=3.5mm,Fr=0.1mm/r,Vc=75m/min

|

|||

|

Machining Effect

|

||||

|

Cutting tools material

|

Cutting speed

|

Feed Rate(mm/r)

|

Lifetime/tip

|

|

|

Halnn BN-K1

|

75m/min

|

0.1

|

85

|

|

|

Ceramic inserts

|

35m/min

|

0.07

|

10

|

|