PCD/PCBN Tools for Rollers

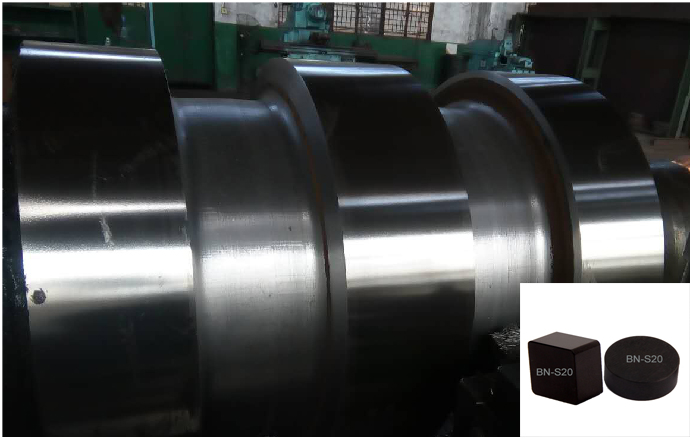

Mill Rolls are Important Tools and Key Components for Rolling Ferrous Metal Materials. the Cost of Mill Rolls is about 5%~15% of the Rolling Steel Production, Which is Directly Related to the Production Efficiency, Product Quality and Production Cost of the Steel Enterprises. Mill Rolls Can be divided into Casting Rolls, Forging Rolls, Tungsten Carbide Rolls. All of them have High Hardness and Large Allowance, and are difficult To Process. Especially for the Large Casting Rolls with the Casting Defects such As Sand, Stomata and Hard Spot , It will required the high hardness of Cutting Tools.

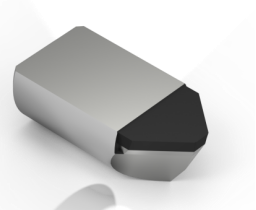

Specific for the High Hardness Rolls, Halnn Tools Recommend the Solid CBN Inserts Which can be used for Large Margin Cutting. Compared with the Traditional Cutting Tools, the Solid CBN Insert’s Performance is more Stable, and the Production Efficiency Will be Improved, and the ary cutting applications significantly reduced the Production Costs. Tungsten Carbide Ring is also called Tungsten Carbide Alloy Roll Ring ( WC Rolls or TC Rolls), We Process them with CBN and PCD Tools . Normally, CBN Inserts are Generally used for Rough Turning Tungsten Carbide Rolls Which Hardness ≤ HRA88. PCD Tools are mostly used for Finish Turning Cylinder, Chamfering and Engraving.

|

RNMN Solid CBN Inserts |

RCMX-V Solid CBN Inserts |

RCMX-Y Solid CBN Inserts |

PCD Notching Tool |

PCD Engraving Tool |

|

|

|

|

|

|

With more than 15 years experience, Halnn have researched one by one new materials Grade, New Technology and become the most Famous Cutting Tools Brand in Superhard Cutting Tools Industry. Specific above Casting defects and other problems, Halnn reserached some CBN Inserts and PCD Tools for Machining these High Hardness Rolls.

|

Halnn Grade

|

Type of Inserts |

Machining Materials |

|

BN-K1 |

Solid CBN Inserts |

High Hardness Cast Iron |

|

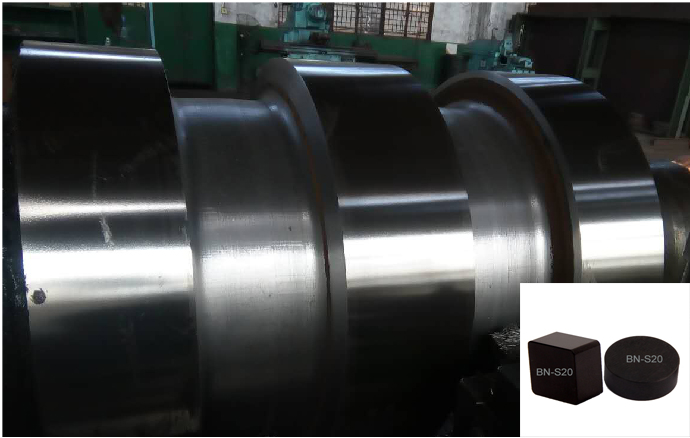

BN-S20 |

Solid CBN Inserts |

High Hardness Steel/ forging Steel |

|

BN-S300 / BN-S200 |

Solid CBN Inserts |

Tungsten Carbide ( ≤ HRC88 Hardness) |

|

CDW010 |

PCD Tools |

Tungsten Carbide Ring |

Recommend Cutting Parameters for Machining Different Materials Mill Rolls

| No. |

Rolls Materials |

Wokring Layer Hardness |

Recommend Cutting Parameters |

|

|

1 |

High Chrome Nickel Cast Iron |

HSD72-82 |

Roughing |

Vc=15-30m/Min,Ap=3-7mm,f=1-2.5mm/r |

|

Semi-Finishing |

Vc=20-40m/Min,Ap=4mm,f=1.5-2.5mm/r |

|||

|

2 |

High Chrome Cast Iron |

HSD72-78 |

Roughing |

Vc=10-20m/Min,Ap=3-7mm,f=0.50-1.2mm/r |

|

Semi-Finishing |

Vc=15-30m/Min Ap=4mm f=1.5-2.5mm/r |

|||

|

3 |

Casting High speed steel |

HSD82-90 |

Vc=5-15m/Min Ap=3-8mm f=1-2.5mm/r |

|

|

4 |

Casting Semi-Steel |

HSD55-65 |

Vc=30-60m/Min Ap=4mm f=1.5-2.5mm/r |

|

|

5 |

High Carton Semi-Steel |

HSD65-72 |

Vc=25-50m/Min Ap=4mm f=1.5-2.5mm/r |

|

|

6 |

Chilled Cast Iron |

HSD50-70 |

Vc=25-50m/Min Ap=4mm f=1.5-2.5mm/r |

|

|

7 |

High Chrome Cast Steel |

HSD68-75 |

Vc=20-45m/Min Ap=4mm f=1.5-2.5mm/r |

|

|

8 |

Tungsten Carbide Rings |

HRA88 |

Vc=15-60m/Min Ap=0.2-0.5mm f=0.1-1 Mm/r |

|

|

9 |

forging 9Cr2Mo |

HSD92-105 |

Vc=10-25m/Min Ap=1mm f=0.5-1.2 Mm/r |

|

Aplication Case

(1). BN-K1 Solid CBN Inserts Rough Machining High Ni-Cr Alloy Cast Iron Rolls

|

Rough Machining High Ni-Cr Alloy Cast Iron Rolls |

|||

|

Machining Material |

Hardness of Workpiece |

Selected Halnn Insert |

Cutting Condition |

|

High Ni-Cr Iron |

HSD80 |

BN-K1 RNMN120400 and SNMN120712 |

Ap=9mm,Fr=0.5mm/r, Vc=25m/min |

|

Selected Insert |

Efficiency |

Workpiece |

|

|

Halnn BN-K1 |

Improved 3 Times |

|

|

|

Carbide Insert |

/ |

||

(2)BN-K1 Solid CBN Inserts Machining Semi-Finishing Chilled Cast Iron Rolls

|

Semi-finishing Chilled Cast Iron Rolls |

|||

|

Machining Material |

Hardness |

Selected Insert |

Cutting Condition |

|

Chilled Cast Iron Rolls |

HSD67 |

BN-K1 SNMN |

Ap=2mm,Fr=0.5mm/r, Vc=66m/min |

|

Selected Insert |

Efficiency |

Lifetime |

Workpiece |

|

Halnn BN-K1 |

Improved 3 times |

3 times |

|

|

|

|

|

|

(3)BN-S20 Solid CBN Inserts Turning High Speed Steel Roll

|

Turning the Repairing Threaded Steel Roll

|

|||

|

Machining Material |

Hardness |

Selected Insert |

Cutting Condition |

|

High speed steel Rolls |

HRC60 |

BN-S20 |

Ap=0.5mm,Fr=0.5mm/r,Vc=25m/min |

|

Selected Insert |

Efficiency |

Workpiece |

|

|

Halnn BN-S20 |

5 times |

|

|

|

Carbide Insert |

/ |

||

(4)BN-S20 Solid CBN Inserts Finish Turning forged Steel Cold Rolls

|

Finish Turning Forged Steel Cold Rolls |

||

|

Machining Material |

Hardness |

Selected Insert |

|

High speed steel Rolls |

HRC60 |

BN-S20 |

|

Selected Insert |

Efficiency |

|

|

Halnn BN-S20 |

5 times |

|

|

Carbide Insert |

/ |

|

(5)Halnn Tools BN-S300 CBN Turning Tungsten Carbide Rings

|

CBN Turning Tungsten Carbide Rings

|

|||

|

Machining Material |

Hardness |

Selected Insert |

Cutting Parameters |

|

Tungsten Carbide Rings |

HRA88 |

BN-S300 |

Vc=15m/min,ap=1mm,fr=0.3mm/r |

|

|

|

||

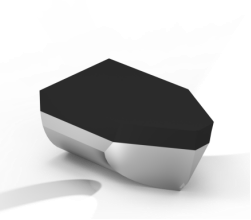

(6)Halnn PCD Tools machining Tungsten Carbide Rolls

PCD Inserts Turning Tungsten Carbide Rolls

|

PCD Turning Tungsten Carbide Rings |

|||

|

Machining Material |

Hardness |

Selected Insert |

Cutting Parameters |

|

Tungsten Carbide Rings |

HRA88 |

CDW010 |

Vc=15m/min,ap=1mm,fr=0.3mm/r |

|

|

|

||

|

PCD Notching Tools |

PCD Notching Tools |

CVD Engraving Tools |

RCMX PCDTools |

|

|

|

|

|