The so-called hard cutting gear refers to the precision cutting process of hardened steel gears with a hardness greater than 50HRC using ceramic or superhard CBN tools. Compared to grinding, hard cutting has good machining flexibility, economy, and environmental performance, which has attracted much attention from the gear industry.

In the process of hard cutting gears, due to the high cutting force and cutting temperature, there are high requirements for cutting tools, such as high heat resistance and wear resistance. Ceramic cutting tools and CBN cutting tools have good heat resistance and wear resistance, and can be processed at high cutting speeds and low feed rates. However, due to their high brittleness, they can only be processed with a small allowance of cutting depth. Conversely, there may be phenomena such as tool breakage.

Ceramic tools are suitable for machining gears between HRC45-55, and CBN tools are more suitable for gears with hardness above HRC58. CBN tools are currently hard tools for machining ferrous metal materials and can process workpieces with hardness between HRC45-79. As a pioneer in the localization of superhard cutting tools, Hualing superhard has been researching and developing CBN cutting tools and high-grade diamonds for brittle and hard material processing in the early stages. It has deep expertise in hard cutting gears, especially the application of BN-H10 brand, which has led to the rapid development of hard cutting technology in the gear industry.

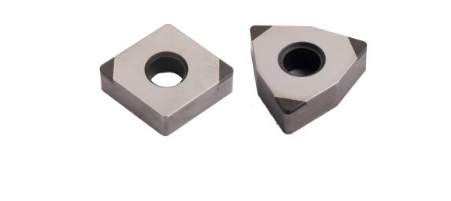

The BN-H10 brand belongs to the composite CBN tool, with only one cutting edge available. However, when cutting gears in a hard state, its excellent wear resistance and heat resistance are unmatched by other companies' multi blade CBN tools.

At the same time, while ensuring the dimensional accuracy and surface quality of gears to reach Ra0.8, it significantly improves production efficiency and reduces production costs.

Taking hard cutting gears as an example: material: 20CrMnTi; Hardness: HRC58-62, machining condition: continuous cutting condition, required surface finish: Ra0.8, blade model: BN-H10 CNGA120408, cutting parameter: Vc=180m/min; Ap=0.2mm; Fr=0.1mm/r, processing method: dry cutting

Compared with a certain brand of CBN blade (as follows): Under the same cutting parameters, the tool life of the BN-H10 brand of Hualing superhard CBN tool is 1.33 times that of a certain brand of CBN tool.

Insert Material | Cutting Speed | Tool Life/edge | Surface finish |

Halnn BN-H10 | 180m/min | 800pcs | Ra 0.8 |

Other CBN | 180m/min | 600pcs | Ra 0.8 |

When BN-H10 composite CBN tools are used for hard cutting gears, dry cutting is generally used without adding cutting fluid. However, sometimes there are special requirements for the machining accuracy, surface quality, and tool life of the workpiece, water-based cutting fluid can also be used for continuous and uniform cooling to avoid micro cracks on the blade.