As one of the main consumption components in automobiles, brake drums have rapidly developed with the rapid development of the automotive industry, and downstream industries such as machining factories have risen. In order to quickly put components into the market, quality issues may have been overlooked. At the same time, brake drums have high requirements for form and position tolerances and surface roughness, resulting in a high proportion of scrap and defective products. In order to achieve higher surface roughness while not affecting the overall processing efficiency, Improvements can be made from tool materials.

Brake drums generally belong to mass production, and manufacturers often use CNC machine tools for processing. CNC machine tools can cut at high speeds to improve the processing efficiency of brake drums, and cutting tools are particularly important at this time. Cutting tools are tools that directly contact the brake drum and cut off the brake drum allowance. Without good quality, they cannot meet the production requirements of high-speed cutting.

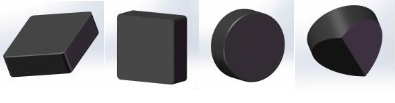

Summary of CBN tool grades for cutting brake drums

Halnn is a pioneer of CBN tools for processing brittle and hard materials. Faced with the quality and efficiency requirements of brake drums, we recommend three CBN tool materials to assist CNC machine tools in efficiently cutting brake drums. These three CBN tool materials are BN-S300, BN-K20, and BNK30, respectively.

BN-S300: It is an integrated polycrystalline CBN tool developed by Hualing Superhard for rough machining of brake drums. After casting, the brake drum blank has a large margin. Using BN-S300 brand CBN tools can cut the brake drum blank margin to a large extent, minimizing the number of tool passes and improving production efficiency.

BN-K20 : It is an embedded CBN tool developed by Halnn Superhard for precision machining processes. Its cutting edges are more economical, and the cutting depth is controlled within 0.3mm, ensuring the shape and position tolerance requirements and surface roughness requirements of the brake drum.

BNK30 : It is a new generation of CBN material developed by Halnn Superhard for cast iron processing. It mainly uses embedded CBN tools, and can also customize overall polycrystalline CBN tools according to user requirements. It can efficiently process brake drums at a cutting speed of 500-2000m/min, meeting the stable cutting requirements of gray cast iron parts such as brake drums. It serves Ford and Fiat automotive components with excellent performance, as well as high-speed milling of Cummins engines in the United States.

Cutting parameter range of Hualing superhard CBN tool for cutting brake drums

Machining material | Recommended cutting parameters | CBN insert Grade |

| Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) |

|

Brake drum | 200-700(Roughing) | 1-10 | 0.2-1 | BN-S300 |

| 300-2000(Finishing) | ≤1 | 0.05-0.3 | BN-K20,BNK30 |