Cr12/Cr12MoV are both cold work die steels, among which Cr12MoV steel has higher hardenability, quenching and tempering hardness, wear resistance and strength than Cr12. Used to manufacture various cold stamping dies and tools with large cross-section, complex shape and heavy working conditions, such as punching die, trimming die, hemming die, steel plate deep drawing die, circular saw, standard tools and gauges, Thread rolling die, etc.

Cr12 cold working die steel is mainly used for cold punching dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, embossing dies, thread rolling boards, drawing dies and threads that bear less impact load and require high wear resistance. Rolling mold, etc.

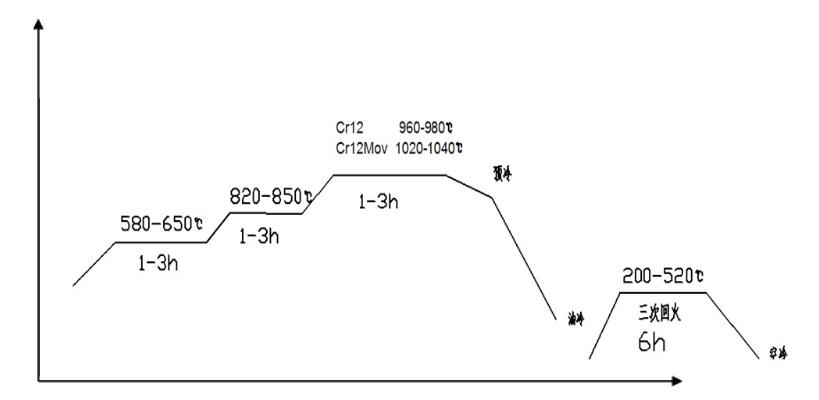

Cr12 quenching process

The workpiece is below 300°C and placed in a furnace, and the furnace is heated to 600-650°C for 0.5-2 hours, then heated to 800-850°C for 0.5-2 hours, and then raised to 950-980°C for 0.5-2 hours. (The heat preservation time depends on the small size of the workpiece)

The tempering of Cr12 steel is mainly based on the empirical tempering equation HRC-64-1/80T (T≤500°C) and HRC=107.5-1/10T (T>500°C) of Cr12 steel and the hardness requirements to determine the tempering temperature.

The quenched workpiece can be heated up with the furnace, or it can be put into the furnace at the same temperature. The holding time is determined according to the size of the workpiece and the tempering temperature, generally 1-3 hours.

Quenching Process of Cr12MoV

In actual heat treatment,

The first preheating temperature: 650℃, the heating time is 30 minutes, and the holding time is 2 hours

Second preheating temperature: 850℃, heating time 20 minutes, holding time 2 hours

The third heating temperature: 1030 ℃, heating time 20 minutes, holding time 1.5 hours

Cooling method: oil cooling. Let cool to oil temperature.

Then in time for the first tempering

Determine the tempering temperature according to the required hardness.

50-55HRC Tempering temperature 530℃

55-60HRC tempering temperature 520℃

>60HRC Tempering temperature <180℃

After tempering, air-cool (with a fan) to room temperature.

Remarks: After tempering once, take it out of the oven to cool down, and then continue tempering. Repeat tempering three times until the required hardness is reached.

Application field and hardness range of Cr12MoV die steel

(1) It is used to make punches, dies and inserts with complex shapes of punching dies with a material thickness > 3mm. The recommended hardness is 58-62HRC when making punches, and 60-64HRC when making dies.

(2) Used to make punches and dies that require high wear resistance in punching dies. The recommended hardness is guanidine 60-62HRC when making punches, and the recommended hardness is 62-64HRC when making concave dies.

(3) It is used to make the concave die that requires tensile resistance in the drawing die, and the recommended hardness is 62-64HRC.

(4) Used to make punches, dies and inserts that require wear resistance and complex shapes in bending dies. The recommended hardness is 60-64HRC when making punches, and the recommended hardness is 60-64HRC when making concave dies

(5) Used to make punches and dies for cold extrusion of aluminum parts. The recommended hardness is 60~62HRC when making punches, and 62-64HRC is recommended when making concave dies.

Application field and hardness range of Cr12 die steel

(1) It is used to make the concave mold that requires wear resistance in the drawing die, and the recommended hardness is 62-64HRC.

(2) When used as a punch for cold extrusion dies of aluminum parts, the recommended hardness is 60-62HRC.

(3) It is used to make punches, dies, and inserts that require high wear resistance and complex shapes in bending dies. When making punches and dies, the recommended hardness is 60-64HRC.

Selection of Machining Tool for Cr12/Cr12MoV Mold after Quenching

Cr12/cr12mov mold steel is mainly used for milling. The hardness and complexity of the shape of the workpiece are different, and the variety of grooves, how deep, whether there is a curved surface, what requirements are on the surface, etc., all determine the material, structure type, and tool selection of the tool. Effective length, number of blades, etc.

According to the different parts of Cr12/cr12mov die steel, choose tools with different structures. For example, flat-bottomed end mills are commonly used for milling the inner and outer contours of parts and milling planes. Milling cutters, drum milling cutters, cone milling cutters and disc milling cutters. At the same time, there are also special mold milling cutters, which are evolved from end mills. According to the material, they are divided into cemented carbide mold milling cutters, high-speed steel mold milling cutters, etc. Carbide mold milling cutters are very versatile, except for milling In addition to various mold cavities, it can also replace hand-used files and grinding wheels to clean the flash of casting, forging, and welding workpieces, and to smooth certain forming surfaces.

For milling Cr12/cr12mov mold steel plane, cubic boron nitride cutting tools are recommended, which have both wear resistance and impact resistance toughness. Compared with cemented carbide tools, they have a longer service life and better surface finish.

Solution parameters of Cr12MoV die plane in CBN tool milling

Workpiece material: cr12mov

Workpiece hardness: HRC65

Insert type: BN-S200 RNGN090300

Cutting parameters: Vc=130m/min, Fr=0.12mm/r, ap=0.5mm

Processing method: dry cutting

Processing results: Compared with other brands CBN inserts, Halnn BN-S200 grade helps customers reduce the cutting tools’ cost for processing a single workpiece by 40%, greatly reducing the cost of cutting tools and improving production efficiency