Machining Pulley with Brazed PCBN Insert BN-K20

Pulley belong to gray cast iron parts, and the precision doesn’t need very high, some workpiece only required the roughness Ra3.2, carbide insert can satisfy the requirements, but with the technology improved, the product roughness and precision required high, the corresponding tools also need better quality and longer tool life.

The best way to lower the cost is changing the tool material. Choosing the cutting tools with high efficiency and good quality not only improve the efficiency, but also reduce the changing times, which will reduce the processing time and the tools costs.

Halnn, as professional manufacturer on machining hard materials, recommended BN-K20 brazed pcbn inserts specific for machining gray cast iron parts pulley. The advantages include:

(1) High hardness, excellent wear resistance, long tool life.

(2) Belongs to cbn inserts with hole, it can use the same holder with carbide insert. It doesn’t need to change the tool holder.

(3) It can be used for high speed cutting, has high efficiency.

(4) Dry Cutting Type will reduce the pollution.

The application case of Halnn BN-K20 Brazed PCBN Inserts machining pulley:

|

|

|

Workpiece Materials: Gray Cast Iron

|

|

|

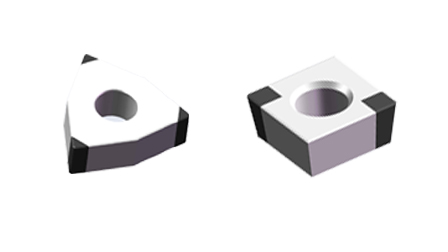

Insert Models: BN-K20 CNGA

|

|

Cutting Data: ap=0.3mm,Fr=0.25mm/r,Vc=550-700m/min

|

|

Machining Type: Dry Cutting

|

|

Testing Performance

|

|

Insert Materials

|

Roughness

|

Insert Life(pcs/blade)

|

|

Halnn BN-K20

|

Ra0.7-Ra1.6

|

200

|

|

Coating Carbide Insert

|

Ra1.6-Ra3.2

|

35

|

Comparing with coated carbide insert, the roughness is better than carbide insert, and the tool life is 5.7 times of carbide insert.

BN-K20 belong to brazed pcbn insert, the cutting edges on both sides can be used, and the cutting speed also can reach 1500/min, it not only make sure high efficiency, but also obtain good roughness, and help the manufacturer reduce the costs.