Halnn, as a professional Manufacturer of researching and producing CBN Insert, always devote to offering service for manufacturers in automotive, steel, Petroleum, chemicals, machinery industry, accumulate lots of successful application case and famous customers.

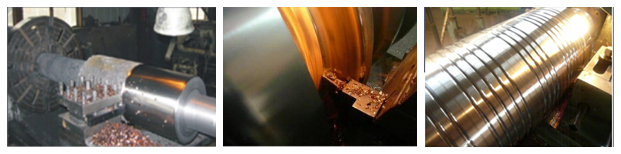

Mill Rolls, as the most important and main wear parts on the rolling mills, manufacturers will often add some metal element in the process in order to make sure the tool life and obtain the rolls durability, such as Chromium, nickel ect. Mill Rolls can be divided in 3 kinds: cast iron rolls, cast steel rolls and forged steel rolls depending on the materials. And specific to above three kinds of mill rolls, Halnn already researched new materials CBN insert to machine, and has very obvious affect.

Specific to cast iron rolls, it has high hardness, so Halnn recommend to BN-K1 Solid CBN insert for roughing and finishing.

BN-K1 belongs to solid CBN insert , mainly used in casting and powder metallurgy industry, and can be used for both finishing and roughing. When BN-K1 Solid CBN insert rough machining alloy rolls, it will have a good chipping resistance and fracture-resistance in a high temperature. Application Case as follows:

Machining Part: Cast iron roll

Machining Materials: High nickel alloy cast iron

Work piece Hardness: HSD 80

Inserts Grade:BN-K1 RNMN200800

Cutting Type: Dry Cutting

Cutting Parameters: ap=4mm,Fr=1mm/r, Vc=55m/min

|

Inserts Materials

|

Feed Rate(mm/r)

|

Lifetime/cutting edge

|

Failure Mode

|

|

Halnn BN-K1

|

1

|

3

|

Normal wear

|

|

Ceramic Inserts

|

0.5

|

0.5

|

Chipping

|

Specific to cast steel rolls and forged steel rolls, the hardness must be more than HSD because of steel materials, it can be used CBN insert. So Halnn recommend to BN-S20 Solid CBN insert for finishing and semi-finishing. And the lifetime will be about 20 times of traditional insert, such as carbide cutting tools.

Application Case as follows:

Machining Part:Hardened Steel roll

Machining Materials: Cobalt-nickel alloy powder spray

Workpiece Hardness: HRC 60

Inserts Grade:BN-S20

Cutting Type: Dry Cutting

Cutting Parameters: ap=1.7mm,Fr=0.7~0.8mm/r,Vc=70m/min

|

Inserts Materials

|

Linear Speed(m/min)

|

Cutting Depth(ap)

|

Failure Mode

|

|

Halnn BN-S20

|

70

|

1.7

|

Normal wear

|

|

Carbide Inserts

|

16

|

0.6

|

Chipping

|

Halnn BN-K1 and BN-S20 CBN insert have already been researched in 2003 and 2005,and also used in mill rolls industry. More than 10 years, Halnn CBN insert already well-known by most manufacturers in China, because Halnn already help many customers solve their problems, improve the processing efficiency and lower the producing cost. Halnn begin to develop the foreign market and also have confidence to help more mill rolls manufacturers solve their problems and let Halnn walk out the world.