As an important transmission component in mechanical equipment, gears are widely used in machine tools, automobiles

and other industries. With the increasingly fierce market competition in the gear industry, how to achieve cost reduction and

efficiency under the conditions of ensuring product quality has become the survival and development of the gear industry.

The key, hard turning is undoubtedly an important way to solve these problems.

The hard turning gear is the turning method of the hardened gear as the final finishing process. The processing quality can

replace the grinding process, which is also called the “turning instead of grinding” process.

Advantages of turning gears compared to grinding processes

Cost: The investment of lathe is only 1/3-1/10 of the grinding machine, which not only reduces the capital investment of machine

tools, but also enables flexible production and efficient use of equipment;

Quality: 80% of the heat generated during the turning of the gears is carried away with the chips, avoiding problems such as

burns and cracks during the grinding process;

Efficiency: Turning efficiency is 4-6 times of grinding;

Environmental aspects: Turning gears are mostly dry-cutting, which enables clean production and ensures a good working

environment,while the chips are easier to recycle.

Tool material selection for turning gears

Hard turning gears have higher performance requirements for cutting tools, especially in the strict dimensional accuracy and surface

finish of gears, and even under strong intermittent cutting conditions. At present, hard-turned gears are mostly processed with imported

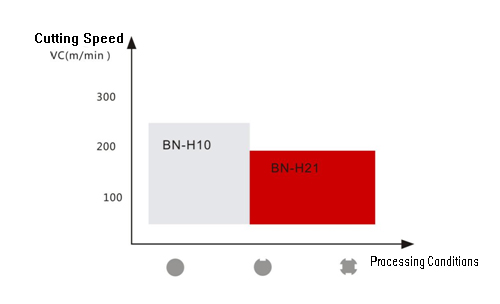

CBN tools. Halnn have developed CBN tools BN-H10 & BN-H21 for continuous cutting and interrupted cutting, respectively. Its excellent

cutting performance has outstanding advantages in the field of hard turning gears, breaking the monopoly of foreign PCBN tool hard

turning gears in China.

Advantages of CBN tools BN-H10 & BN-H21 hard turning gears

Case of CBN tools BN-H10&BN-H21 hard turning gears

1,Halnn CBN tools BN-H10 continuous turning gear inner hole

|

Halnn CBN tools BN-H10 continuous turning gear inner hole. |

|

Processing conditions: continuous hard turning

Workpiece hardness: HRC58-62

Tools type: BN-H10 CNGA120408

Cutting parameters: Cutting speed(Vc)=180m/min,

Feed rate(Fr)=0.1mm/r,

Cutting depth(ap)=0.2mm

Processing method: dry cutting

|

Tool material

|

Cuttingspeed(Vc)m/min |

Tool life pcs/edge

|

Production beat s/pcs

|

|

Halnn BN-H10 |

180m/min |

800 |

6s |

a European ceramic cutter

|

130m/min |

150 |

8.5s |

2,Halnn compound CBN tools BN-H21 interrupted cutting gear end

Halnn compound CBN tools BN-H21 interrupted cutting gear end

|

|

Processing conditions: heavy interrupted turning

Workpiece hardness: HRC58-62

Tool type: BN-H21 WNGA080408

Cutting parameters: Cutting speed (Vc)=300m/min,

Feed rate(Fr)=0.1mm/r,

Cutting depth(ap)=0.3mm

Processing method: dry cutting

|

|

Tool material |

Cutting speed (Vc) m/min |

Cutting depth(ap) mm |

Production beat pcs/edge |

|

Halnn BN-H21 |

300 |

0.3 |

600 |

|

a European CBN tools |

300 |

0.3 |

450 |