Engine block processing CBN inserts - BN-S300& BNK30 CBN

As one of the five major components of the engine, the engine block is the basis for all parts of the engine. Generally,gray

cast iron with good strength, rigidity, wear resistance and corrosion resistance is used as the application material, but the

engine block requires its higher quality, such as the flatness of the upper and lower planes of the cylinder requires 0.03mm,

the standard value of cylinder roundness and cylindricity is 0.004mm, the vertical plane of the top plane and the front and

rear end faces is 0.03mm, and the top plane roughness of the cylinder is Ra1. 6 and so on.

At this time, Halnn super-hard CBN insert is selected, which not only can mill the end face of the engine block at high speed,

but also can finish the engine cylinder hole with high precision to ensure high surface finish and flatness.

1. Halnn CBN inserts for machining engine block

BN-S300 & BNK30 CBN grade inserts

BN-S300 CBN grade inserts belongs to the solid CBN insert, its CBN content is up to 91%, the hardness reaches HV3400-HV3600,

which can realize rough milling and finishing milling engine cylinder plane.

BNK30 CBN grade inserts belongs to brazed CBN inserts, only the cutting edge part is CBN material, so it is used to fine boring

the engine cylinder hole process to ensure the surface roughness and roundness and cylindricity requirements of the cylinder bore.

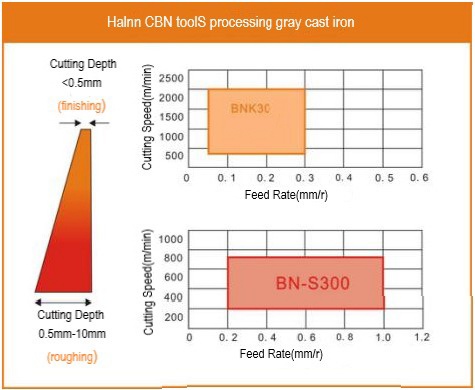

2.Cutting range of Halnn CBN inserts

3. Case parameters of Halnn CBN inserts for milling engine block

|

Case parameters of Halnn CBN inserts for milling engine block |

|

Machining workpiece |

Engine block (HB170-210)

|

|

Workpiece material |

grey cast iron |

|

Processing |

Finishing end face |

|

Type |

BN-S300 SNEN090308ENS |

|

Cutting parameter |

Vc=1700m/min,Fr=0.12mm/r,ap=0.3mm |

|

Processing methods |

Dry cutting |

|

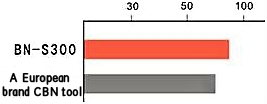

The tool life is increased by 6% under the same cutting parameters. |

Single blade life (edge/ piece)

|