With the increasingly fierce competition in the brake disc market, in order to improve product quality, shorten production cycle, save

production costs, and enhance the market competitiveness of enterprises, high-speed machining is undoubtedly an important condition

to solve the above problems. In this regard, Halnn launch BNK30 material, significant advantages in the field of high-speed processing

brake discs.

BNK30 material uses nano-scale binder and high-purity CBN particles in the best ratio, excellent wear resistance and high temperature

red hardness, which makes it have longer tool life in continuous high-speed cutting, greatly improving productivity, and special welding.

The process greatly improves the peeling resistance and is mainly used for the finishing process of the brake discs.

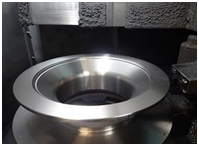

Case of BNK30 material high speed machining brake discs.

|

Comparison of cutting parameters |

|

Test location: a well-known brake disc factory in Germany

Workpiece material: HT250(GG25)

Processing: Finishing

Workpiece diameter: φ434

Workpiece hardness:HB180-241

Judging criteria: surface roughness (Ra1.6)

|

Tool material

|

Halnn BNK30 CBN grade inserts |

An international first-line brand CBN inserts

|

|

Inserts type |

CNGA120408 |

CNGA120408 |

|

Cutting speed Vc(m/min) |

800 |

800 |

|

Feed rate Fr(mm/r) |

0.2 |

0.2 |

|

Cutting depth ap(mm) |

0.25 |

0.25 |

|

Chip shape |

Chips |

Chips |

Coolant (dry cut, wet cut)

|

Dry cutting

|

Dry cutting

|

cutting sound

|

normal

|

normal

|

Surface roughness (Ra)

|

Ra1.6 |

Ra1.6 |

Processing quantity (piece)

|

300 |

195 |

|

Tool life |

Increase by 35%

|

---- |

The above is the use case of an important customer developed by our company's international trade department. The results of

the trialsshocked the customers and said: "I can't believe that Chinese manufacturing can be so powerful." The impression that

Chinese manufacturing is cheap andpoor quality has completely changed, and formed a long-term partnership with Halnn.