Part 1 The Materials of the Gearbox

In past times, the gearbox is made of gray cast iron, which is easily forming, and has good shock absorption and low costs. With the users’ increasing requirements for driving comfort of the cars and the mature trength of the lightweight technology, the gearbox is replaced by die-cast aluminum.

Nowadays, the materials of the gearbox are mainly include gray cast iron and die-cast aluminum.

Part 2 Difficulties of machining gearbox

1. It has so many different machining site, we need to change the cutting tools and lathe frequently.

2. It requires high precision, and can’t easily promise the accuracy with common lathe. The efficiency can’t improve easily.

3. It has complex shapes, and most parts are Thin-walled shell, which has bad rigidity, and is difficult to install.

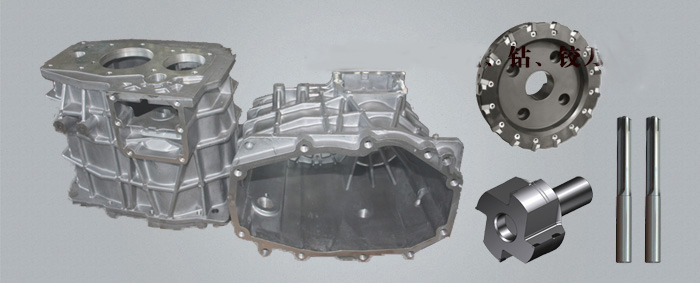

Part 3 The cutting tools of machining gearbox

In current times,the gearbox are belong to bulk order, if with traditional carbide inserts machining gray cast iron and die-cast aluminum casing, the inserts will be wear rapidly because of the high cutting speed, which will lead to the short tool life of the insert. So we launch cbn inserts and pcd tools for machining cast iron and die-cast aluminum casing, which can extend the tool life and improve the efficiency and the product quality.

Part 4 The application of cbn inserts used for gray cast iron gearbox

Milling Surface: BN-S300 CBN Inserts can be used with 2000m/min high speed milling, which will be about 5~6 times than that of the carbide inserts, the surface roughness can be ensured within Ra1.6.

Boring Process:Boring process is one of the key point. In order to make sure the surface roughness and the position precision, it usually use cnc center. BNK30 cbn grade can extand the tool life and improve the efficiency.

Part 5 The application of the pcd tools used for die-cast aluminum gearbox

When machining die-cast aluminum gearbox, we usually use finish boring and finish milling process, not the grinding process, the tips should be more sharp, and reduce the cutting resistance.

For milling the surface of the die-cast aluminum gearbox, we recomment CDW010 PCD Grade, which has good abrasive resistance, high efficiency, the milling speed can reach 3000m/min,which can obtain excellent machining characteristics. For some application which require high surface roughness, also can choose wiper pcd inserts.

For machining the bearing hole of the die-cast aluminum, we recommed PCD Reamers with special tips, which can avoid the shockness caused by the low rigidity, low strength of the gearbox. Internal cold design can improve the tool life. We also can produce the tool depending on the customer’s drawing.

If you would like to know more details about Halnn PCD Tools and CBN Inserts, please feel free to contact with us info@halnntools.com