At present, there are two manufacturing methods for diamond reamers, the outer plating method and the inner plating method. The outer plating method is simple and fast. It is formed by electroplating diamond particles directly on the cutter body through a metal bond (nickel, iron or copper, etc.). But there are also disadvantages.

The inner plating method is more complicated than the outer plating method. It is necessary to make a high-precision mold with the opposite shape of the tool, electroplate diamond abrasive grains on the inner surface of the tire mold to thicken to form an electroplated layer, and then bond the plating layer and the tool holder together to form a diamond reamer, but the accuracy and service life obtained are higher than those of the external plating method diamond reamer.

The following specifically introduces the advantages and disadvantages of the outer plating method and the inner plating method diamond reamer.

Outside plating method:

Outside plating method:

(1) The diamond particles are in a "free state", and they are electroplated irregularly on the tool holder substrate, and are not completely equal in height.

(2) There are inevitably some metal nodules on the circumferential surface of the reamer after electroplating, and its geometric accuracy is very poor, which directly reduces the processing quality of the workpiece

(3) The external plating method reamer must be properly ground before use. The grinding process is costly. At the same time, the grinding damages the natural cutting edge of the diamond particles and causes passivation.

(4) However, most of the diamond particles are flush with the binder, which significantly reduces the cutting ability of the reamer and affects the processing efficiency and the service life of the tool.

Inner plating method:

(1) The tops of the diamond particles are neatly arranged on the inner surface of the mold, with good contour and uniformity;

(2) No need to grind, the micro blade is sharp;

(3) The dimensional accuracy and geometric accuracy of the machined holes are high, the surface roughness is small, and the service life is long.

So far, the inner-containment electroplating technology has been successfully applied to the manufacture of high-precision diamond rollers, but it has not been used to manufacture diamond reamers. At home and abroad, the main plating method is outside.

Solution parameters of electroplated diamond reamer for reaming the hole in the valve body

Take as an example the hole in the valve body of the combined control valve of the upper car used for the reaming crane:

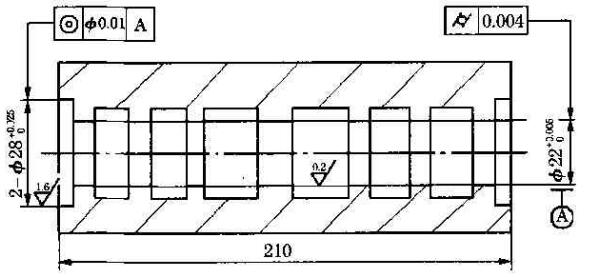

The technical requirements for the inner hole of the telescopic valve body (the material is QT500-5) of the combined control valve QYZ25/20A (8-ton unified valve) on the upper car: the main hole length-to-diameter ratio of the valve body is L/D≈10, and the inner hole diameter tolerance is 0.005mm, cylindricity 0.004mm, surface roughness Ra≤0.2μm.

Halnn diamond reamer size selection: φ22 diamond reamer, three cuts 5mm (width) × 3mm (depth) spiral groove.

The diamond grain size and reaming allowance parameters of the three processes of the Halnn diamond reamer

|

processes |

Diamond granularity |

Reaming allowance/mm |

|

Roughing reaming |

100#-120# |

0.02-0.04 |

|

Semi-finishing reaming |

150#-180# |

0.008-0.01 |

|

Finishing reaming |

240#-320# |

0.004-0.006 |

The reaming parameters of Halnn diamond reamer: speed 80-120r/min, feed 0.3mm/r.

The cutting fluid of the reaming valve body inner controll: the coolant is 90% kerosene + 10% vulcanized cutting oil (or engine oil), or all kerosene.

The supply of cutting fluid is 5-15L/min, and it is better to supply fluid with a pressure of about 0.6MPa when conditions permit. In order to extend the life of the reamer, the cutting fluid should be filtered through sponge, copper wire mesh, magnetic separator or magnetic paper to meet the purification requirements.

Result: The main hole of the valve body reamed by Halnn diamond reamer meets the technical requirements, and the product qualification rate reaches 100%.